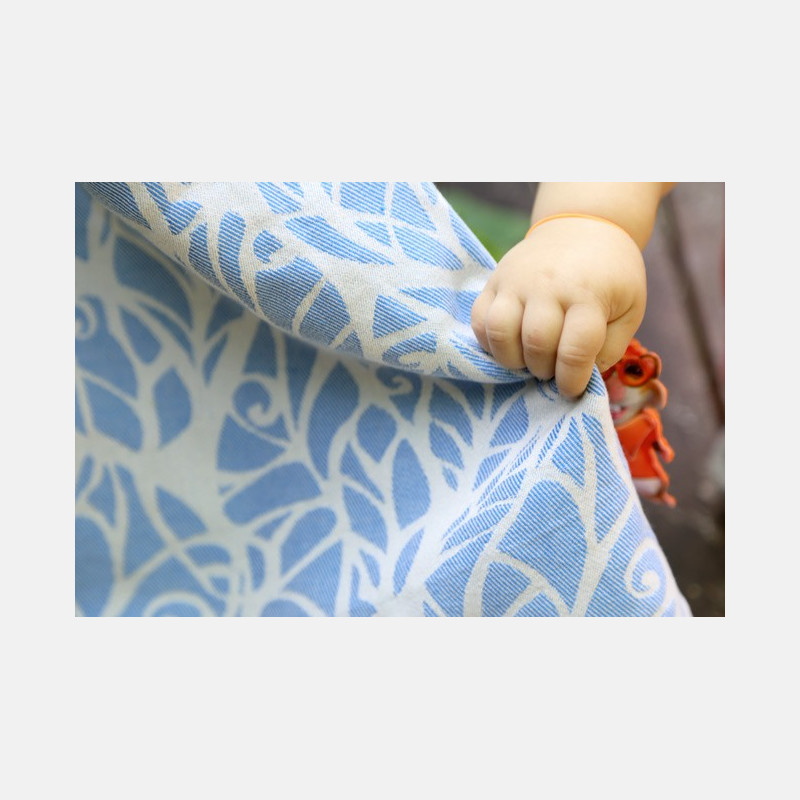

50% ecru Egyptian cotton, 50% cornflower blue natural bamboo (bamboo linen), 265 gr/m2

size 2 long - 140€, size 3 - 155€, size 3 long - 165€, size 4 - 180€, size 5 - 205€, size 6 - 230€, size 7 - 255€

This wrap has natural bamboo yarn in the weft, also called bamboo linen, which should not be confused with the bamboo viscose. This is a medium-weight wrap, suitable for all experience levels. The bamboo yarn in the wrap has a behavior similar to linen, including very occasional nubs and slubs, but needs a shorter breaking in period and gets much softer. The wrap has a luxurious shimmer under the sun, feels smooth in hand, but is grippy and stays in place once wrapped.

After a proper wash and a steam ironing the wrap becomes moldable, floppy and soft. It is gentle for your shoulders and cushy. The wrap is great to use for babies and toddlers.

* The River Dee is a river in Aberdeenshire, Scotland.

* There are two ways of processing the bamboo plant to create yarn. The first is a mechanical process, creating what is informally called bamboo linen, and the second, more popular approach, is the chemical process used for producing rayon or viscose fabric.

Mechanically produced bamboo - natural bamboo (bamboo linen)

Mechanically produced bamboo yarn requires no chemicals, pesticides or fungicides. Using a process similar to the one that produces linen from flax, bamboo fibers are raked and combed into long strands. The fibers are then drawn out and spun into a yarn that is silky and smooth to the touch.

There is very little natural bamboo on the market and the yarn is hard to find, becuse the production process is more labor intensive and costly.

Chemically processed bamboo

The method for producing bamboo viscose yarn requires a series of steps similar to those used for other rayon yarns. The process uses chemical solvents to dissolve the bamboo cellulose into a viscose solution.

Hydrogen peroxide is added as a stabilizer and the solution is forced through spinnerets into a hardening bath which causes thin streams of viscose bamboo solution to harden into bamboo cellulose fiber threads.

The hardening bath is usually a solution of water and methanol, ethanol or a similar alcohol. The regenerated bamboo fiber threads can then be spun into bamboo yarn for weaving into fabric.